Food packaging for liquid products: Stoppil solutions

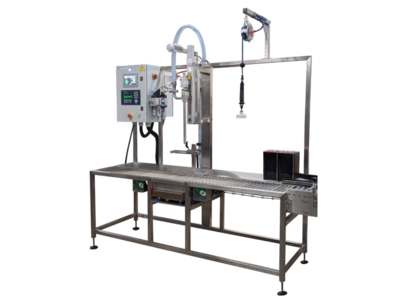

Food products and animal feed require packaging solutions that protect against contamination. With 50 years of expertise in liquid dosing, Stoppil offers machines that guarantee excellent cleaning. Clean-in-Place (CIP) technology is provided depending on the range of filling machine.

Sauces

Oils and vinegars

Beverages

Packaging liquid food products: expertise we have mastered

We are experts in packaging all types of liquid, viscous, and foaming products starting at 5 ml.

Our equipment can be adapted to a wide range of food products:

- Sauces, flavorings, syrups, coulis, caramels, liquid eggs, mayonnaise, and more. These liquids, which vary in viscosity, require precise dosing and careful handling to preserve their texture and organoleptic properties.

- Oils and two-phase products. Our machines, equipped with mass flow meters, are perfectly suited to oil dosing. They guarantee homogeneous and regular product distribution. We also handle two-phase liquids by installing a double dosing circuit in the machines.

- Alcohols. Our filling, capping, and labeling machines are suitable for packaging your bottles of cognac, rum, vodka, liqueur, and other alcohols produced in your artisanal or industrial distilleries.

Here are the dosing technologies we offer for your food products:

- Weight filling and flow meters in semi-automatic machines

- Flow meters and peristaltic in automatic machines

Our machines ensure full compliance with certification requirements for the food industry. We invite you to discover our packaging line solutions for food products, designed to optimize your productivity while meeting the most demanding hygiene standards.

Would you like to submit your project to us? Contact us via our form or by phone: +33 (0)1 60 31 55 55.

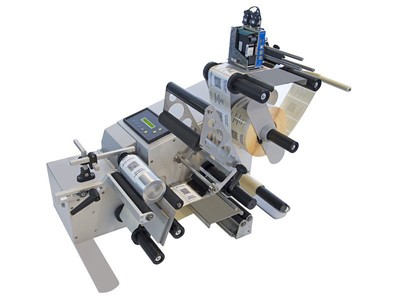

Our multi-format machines for food packaging

The flexibility of the tool is a major asset in the food industry, where product range diversification is intensifying. Our multi-format machines can be adapted to all your containers and caps: bottles, jars, flasks, and cans, whether made of glass or plastic. This technical versatility in the choice of packaging allows you to reduce your investment in equipment while maintaining efficient production for all types of food (fruit purees, vegetable sauces, coulis, etc.).

What are the specific features of our food packaging lines?

Food packaging imposes particular technical constraints that we have mastered perfectly.

- Our equipment incorporates electromagnetic or mass flow meters that guarantee optimal cleaning thanks to the total absence of retention zones. This eliminates the risk of cross-contamination and facilitates cleaning operations.

- Clean-in-place (CIP) is available on most of our machines, ensuring quick, complete, and uniform maintenance of the equipment. This technology eliminates any potentially contaminating residues and guarantees compliance with the strictest hygiene and food safety standards required in the food industry.

- Finally, depending on the nature of the liquid to be filled, we use crimped piping to prevent product retention or poorly cleaned areas. This customized approach ensures optimal adaptation to the specific characteristics of each food product, thus facilitating the implementation of packaging that complies with regulations.

The advantages of STOPPIL linear fillers for the food industry

The choice of dosing technology depends mainly on the characteristics of your product and your production volumes. STOPPIL mainly offers linear filling machines, a technology particularly suited to speeds of up to 5,000 bottles per hour. This specialization allows us to offer economical and flexible solutions for your food packaging needs.

The main advantage of linear filling machines over rotary machines is their operating cost: no specific tooling is required for each bottle format to be packaged. This technical versatility is a considerable asset for food companies with multiple product references or formats.

Our automatic linear diving filling machines package all liquid and viscous products. Designed with high-end components, these scalable machines include up to 12 filling heads, offering production capacity tailored to your needs. This technology ensures optimal protection for your food products.

What other products do we package?

Beyond food, we specialize in packaging a wide range of liquid products in the cosmetics, pharmaceutical, and chemical industries.

We package all industrial chemicals, from household detergents to professional cleaning products. Our packaging machines are designed to handle the specific properties of these liquids, whether they are viscous, corrosive, or have special chemical characteristics. Household cleaning products are an important part of this segment: dishwashing liquids, multi-surface cleaners, industrial degreasers, and specialized cleaning products.

In the cosmetics field, our machines are suitable for creams, lotions, serums, beauty oils, and liquid makeup products. Our filling and capping monoblocks enable fast and hygienic packaging, particularly suited to the requirements of this sector where contamination must be absolutely avoided.

For the pharmaceutical sector, our equipment processes syrups, medicinal solutions, liquid food supplements, and medical hygiene products. The precision of our dosing machines is essential to ensure compliance with prescribed therapeutic dosages.