Our range of automatic filling machines

Our range of automatic filling machines offers different models to meet industry requirements. These filling machines guarantee precise dosing and optimal operation for all types of liquids. Their major advantage is that they do not require any specific tools for each container format!

Automatic linear diving filling machine

Our automatic linear diving filler packages all liquid and viscous products and is particularly suitable for foaming products. This scalable filling machine can be equipped with 1 to 12 filling heads depending on your production capacity needs!

Equipped with volumetric, electromagnetic, or mass flow meters, it guarantees consistent and accurate filling with even product distribution. The total absence of retention zones—in the case of mass and electromagnetic flow meters—ensures optimal hygienic filling. The stainless steel construction guarantees durability and compatibility with most products.

Standard and Premium automatic linear filling machines

Our Standard and Premium automatic fillers offer different features depending on your production criteria. These filling machines efficiently process fluid, viscous, and foaming liquids with high dosing accuracy. The filling system allows for precise control of the filling volume.

Automatic peristaltic filling machine

Our peristaltic pump filling machine is suitable for products requiring particularly hygienic packaging and small volumes (dosing between 1 ml and 1 l). This filling machine offers single-use product circuits if necessary, particularly suitable for the pharmaceutical sector. Peristaltic technology guarantees efficient filling without cross-contamination!

Ecopil non-upgradable automatic linear filling machine

For simple applications on a tight budget, our non-upgradable Ecopil filler offers an economical solution. This filling machine offers the essential performance for filling bottles, vials, and cans at speeds of up to 1,200 bottles/hour.

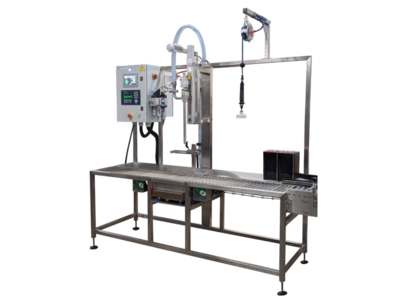

Our semi-automatic weight and flow-meter filling machines

Our semi-automatic weight and flow-meter filling machines offer great operational versatility. The operator can easily manage format changes and special productions.

The semi-automatic operation allows each container to be filled precisely according to the required size.

Available configurations:

- Table format for small batch production

- Wall-mounted or mobile dosing stations to optimize space

- Adaptability to different containers: bottles, vials, drumss

- Easy parameter adjustment

- Corrosive products or ATEX version

All our customers questions about Stoppil filling machines