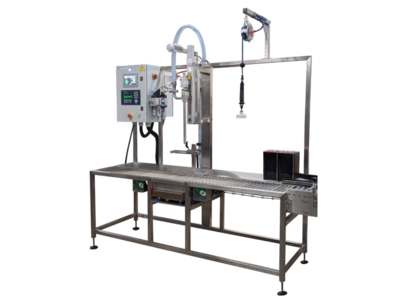

The Stoppil mobile filling station meets your needs for filling directly onto pallets with optimal mobility for your production workshops.

The machine is equipped with a volumetric, electromagnetic, or mass flow meter depending on your product, ensuring precise dosing adapted to the specific characteristics of each liquid. The electronic control board coordinates all filling operations.

What are the advantages of this mobile station? The trolley offers remarkable flexibility of use thanks to its 2 or 4 casters, allowing easy movement between your different packaging areas. This mobile machine handles drums from 5 to 1000 liters with filling directly onto pallets, eliminating costly handling operations.

Please note: the station is also available in a version adapted for corrosive products or products that are not compatible with stainless steel, which broadens the range of applications to include aggressive liquids requiring specific materials.